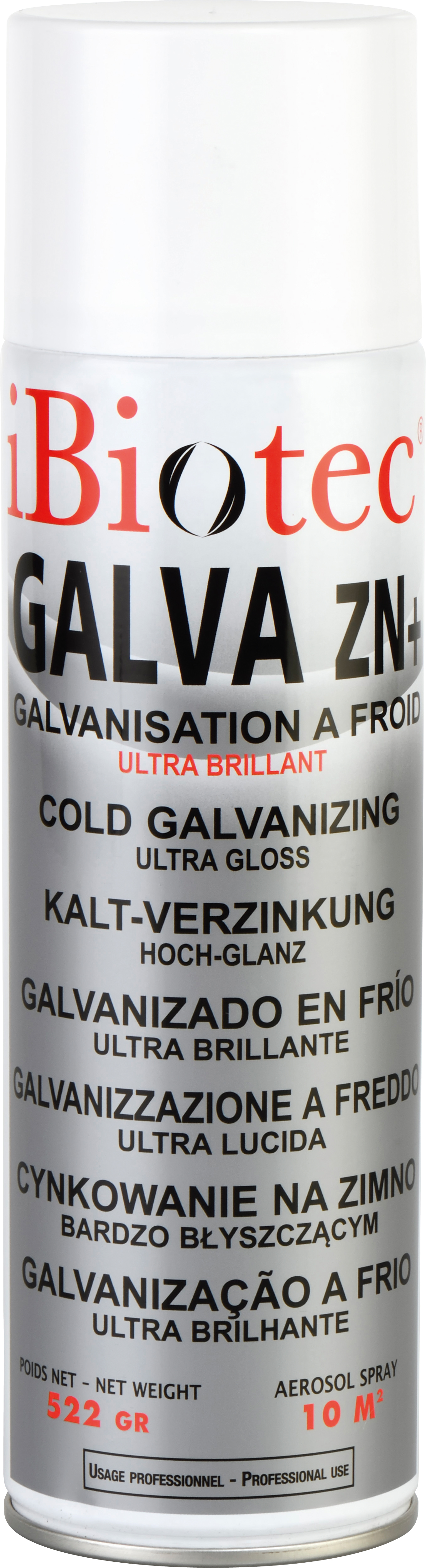

COLD GALVANISING AEROSOL

METALLISATION RETOUCHING FINISH

AREA COVERED PER AEROSOL : 10 m²

USABLE FROM -50°C TO +550°C. WELDABLE - PAINTABLE

TEST RESULTS – SALINE FOG – RI 5 more than 2,800 h

MINUTES OF ANALYSIS BY INTERTEK LABORATORIES (with COFRAC and ISO 17.025 certification)

N°PVA-CHL-R14-0135D-A01 dated 28.07.2014

This expertise report can be sent to you upon simple request, using the contact card

DRYING TIME

Dust dry at 25°C : 4 minutes 30

Drying time at 25°C before lhandling : 7 minutes

Total curing time at 25°C : 24 heures

DESCRIPTION

Cold galvanising aerosol with high zinc content, recommended for long-term protection of all metallic parts (iron or alloy types).

Ensures galvanising coatings which have a consistent thickness, with a homogenous and ultra-shiny appearance.

Film which is distinguished by the high quality of its appearance.

Cold galvanising aerosol Zn+ iBiotec, resistant at temperatures up to 550 °C without deteriorating. This characteristic allows the user to do any job with it, on bodies which are subjected to very high temperatures. In addition, the coating produced is solderable (except with argon).

This cold galvanisation aerosol offers several benefits:

- Galvanic protection (with oxidation reduction principle), obtained at 100 %.

- Protection against thermal corrosion, but also chemical corrosion.

- Film left (with no drips and no excess thickness; and it does not deteriorate during applications) on screwed joints.

- Very high hedging power, can be dusted away quickly, allowing for application on all types of sites.

- Perfect finish with ultra-shiny appearance.

- Paintable after total polymerisation (24 hours at 25 °C), with all types of paint.

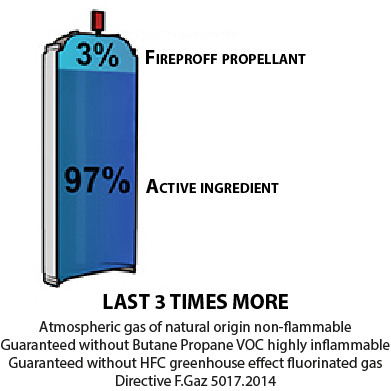

- No need to purge the aerosol after the application.

This galvanisant allows for versatile action: for the protection of all galvanised metals; after mechanical recovery or welding; as well as for prevention of corrosion and oxidisation.

USAGE DOMAINS

Galvanic protection.

Protection of all uncoated metallic parts.

Recovery of hot-dip galvanised parts.

Appearance treatment.

Recovery after machining or welding.

Preparation of surfaces.

EDF poles, guardrails, sign boards.

Industrial chimneys, flanges, pipes, fittings.

Racks of machines, housings, bodies, architectural elements.

Rivet heads, fasteners, roof pins, screw connections.

Electric motor bodies, pump bodies, water meters.

Hinges, metal doors, metal frames.

Fences, enclosures, openings.

Sanitary installations, heat pumps, air conditioning units.

Heating installations, regresses with sealing tanks.

Electrical equipment, rolling stock, sanitary installations.

Protection of nails or screws before plaster coating.

Carpentry, metalwork.

Water purification and treatment facilities.

Livestock building.

Urban furniture.

MORE HOMOGENOUS

The galvanisant GALVA ZN+ULTRA SHINY, when applied (not to excess) on all parts which are to be protected from corrosion, allows for the realisation of homogenous film, with no drips or orange peel.

MORE PROTECTIVE

The norm NF ISO 9227 defines the test conditions for the salt spray test and enables the protection of a surface with a coating which protects it against physical, chemical and biological agents.

The norm ISO 4628/3 allows for evaluation of the degree of rusting at the end of the test.

MORE RESISTANT

After polymerisation, coatings are particularly adherent to surfaces, they have excellent scratch resistance and they do not transfer when they are being manipulated.

This adhesion is acknowledged during slow stamping tests as per the norm NF EN ISO 1520, after which appearance changes, cracks and peelings off are observed.

TYPICAL PHYSICAL AND CHEMICAL PROPERTIES

|

CHARACTERISTIC |

STANDARD or METHOD |

VALUE |

UNITS |

|

Finish |

- |

paint |

- |

|

Colour |

- |

high gloss |

- |

|

Gloss |

Specular reflection Reference 1.567 value 20°/20° |

>90 |

µb |

|

Density |

NF EN ISO 2811.1 |

1.105 |

g/ml |

|

Wet film thickness |

Depth gauge |

10 |

µm |

|

Dry film thickness |

magnetic induction |

6 |

µm |

|

Dust-dry time |

ASTM D 5895 |

4,30 |

min |

|

Time before handling |

ASTM D 5895 |

7 |

min |

|

Fully cured time |

ASTM D 5895 |

24 |

hr |

|

Cross-hatch test |

ISO 2409 |

no deterioration |

- |

|

Stamping test |

ERICHSEN |

film not damaged |

- |

|

Wet abrasion resistance 28 days, 23°C, 50% relative humidity |

ISO 11.998 |

class 1 |

value |

|

Shear strength Tightening torque 80N/m |

MIL A 907 ED |

100 |

% |

|

Temperature resistance |

as per MIL A 907 ED |

-50 +550 |

°C |

|

Specific coverage RSc m²/g per aerosol |

NFT 30.001 |

10,1 |

m² |

|

Salt spray test |

ISO 9227 ISO 4623-3 |

2808 RI 5 |

hr - |

DIRECTIONS FOR USE

Shake the aerosol thoroughly, in an up-and-down movement, after releasing the ball in the can. Spray from a distance of 15 to 20 cm from the surfaces to be treated, avoiding excess thickness and using criss-crossing strokes as necessary. To avoid adhesion problems, do not spray from a greater distance. The principle of galvanisation is that the zinc particles must bind chemically to the iron atoms in order to achieve extremely low oxidation. Surfaces to be treated must be prepared with care to ensure long-lasting protection. It is therefore essential that surfaces are degreased, clean and dry, and are free of grease and traces of rust or scale. Clean with a metal brush or sand the surface if necessary. Aerosol may be used in any position. Do not purge the aerosol after use.

Tip : store the aerosols lying flat to reduce the shaking time needed.

PRESENTATION

|

|

Aerosol 650 ml

|

Looking for another product?

Discover our entire range by clicking on the photo

Manufacturing, lubrification, cleansing, protection,

IBiotec® Tec Industries® Service

offers a wide range of products reserved for industrial area

If you wish for :

a free sample

a technical advice

a product data sheet

a safety data sheet

IBiotec® Tec Industries®Service

manufacturer of technical chemical products.

Welcome to our website.